Resilient Power Control Module RPCM

Datasheet, marketing materials RPCM 1502

Datasheet, marketing materials RPCM 1532

We introduce RPCM, a power management device for remote power control of equipment.

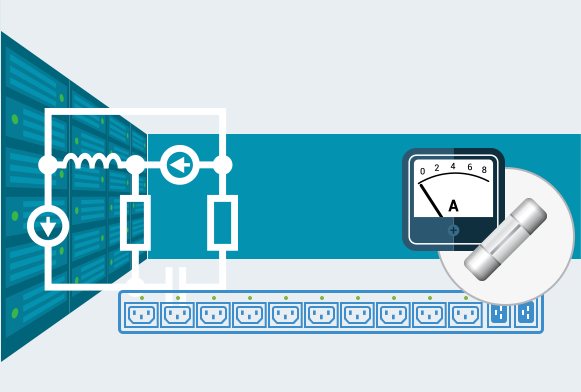

RPCM combines functions of remote power management, automatic transfer switching without interruption of connected devices, short circuit protection and power consumption metering at each outlet independently.

RPCM has 2 power inputs and 10 power outlets.

Features & benefits

|

|

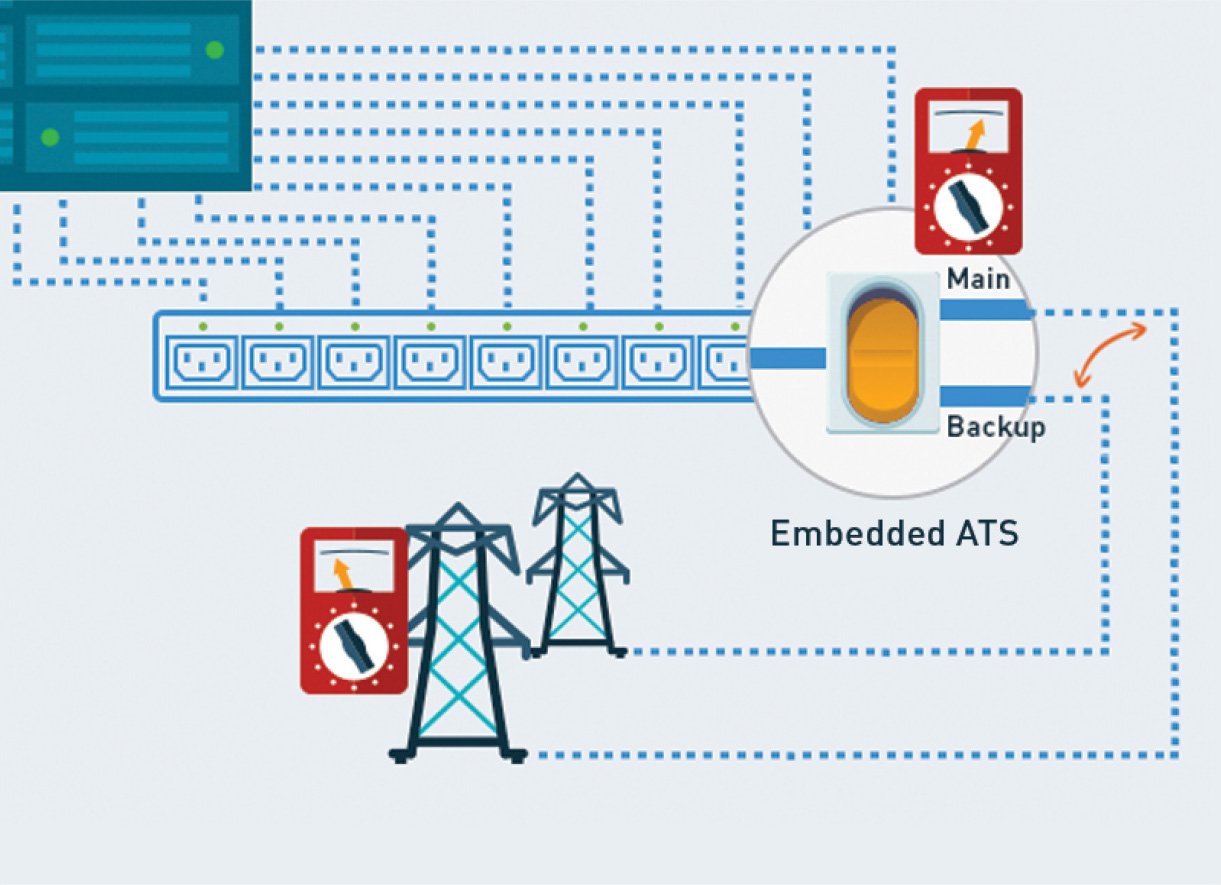

ATS (Automatic Transfer Switch) If power on an input is lost or drops in quality, the device automatically switches consumers to another input without interruption to power supply. |

|

Remote power management of individual outlets System administrators can turn on/off and reset any of the 10 outlets without having to go to the location of the equipment, as well as handle cases where the equipment was turned on/off without authorization, was accidentally unplugged, or experienced a power supply failure. |

|

|

Outlet level short circuit protection If a short circuit occurs on one of the connected devices, RPCM will automatically cut off only the power going to it, thereby keeping the remaining devices up and running - both the one connected to RPCM and the others connected to the same busbar. Since ATS is used for backup power supply, short circuit protection helps prevent both inputs to the rack from being turned off, while also preventing the equipment's power supply on the rack from shutting down as a result of a short circuit on one of the consumers. It also helps obviate the painstaking process of having to locate the failed consumer affected by the short circuit prior to restoring power supply on the rack. |

|

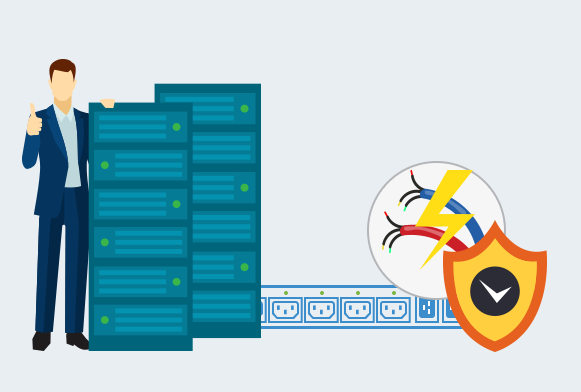

Proper grounding diagnostics RPCM prevents failures and equipment malfunction. It also increases power safety during equipment use thanks to automatic monitoring and proper grounding indication. |

|

|

Configurable electrical current consumption limits for each outlet System administrators can prevent fire hazards from occurring by setting individual limits on current consumption on each outlet, through administrator notifications, or by automatically cutting off power supply to a consumer that has exceeded the defined limit. |

|

Customizable activation sequence and delay of outlets to initiate service correctly and eliminate inrush currents System administrators can essentially guarantee the equipment is turned on after a complete outage. Also, they can define the activation sequence and delay when turning on the equipment after the outage, which allows them to correctly launch the IT infrastructure and information systems. |

|

|

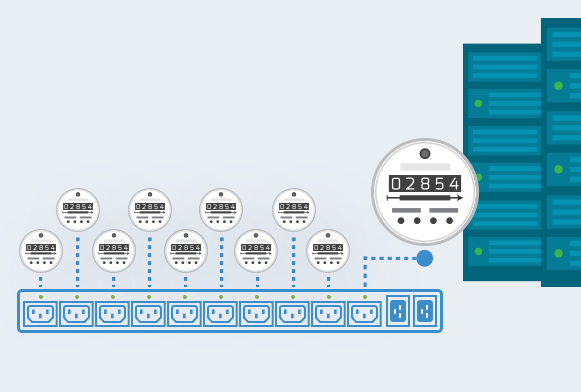

Power meters on each individual outlet Commercial data processing centers can offer clients better prices on colocation when compared with competitors, as it's possible to measure power consumption for each client device. |

|

Highest density of controllable power supply outlets with power meters per 1U in the industry for systems with ATS 10 manageable outlets per unit. As a result, one less power management device is required per rack when compared to competitors. |

Automatic Transfer Switch (ATS)

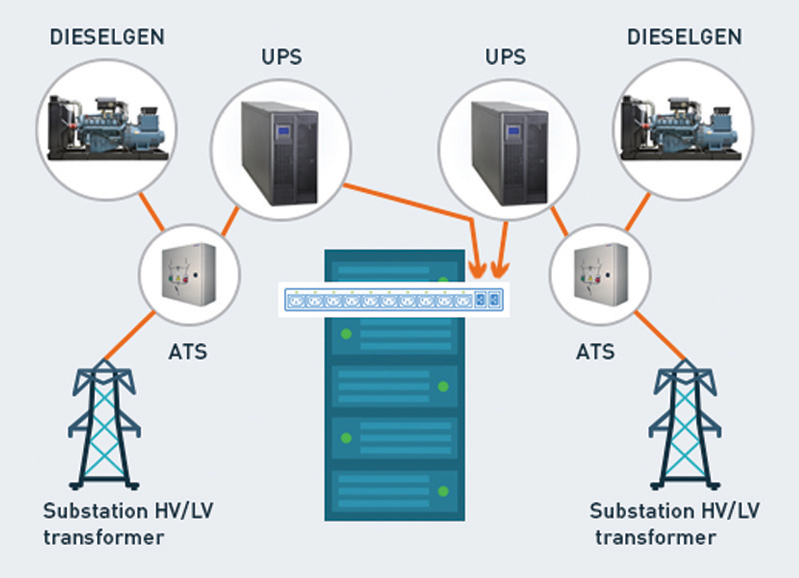

Power in today's data centers is usually supplied by 2 independent inputs, each protected by its own uninterrupted power supply (UPS) and diesel generator sets DGS (Dieselgen) or diesel rotor UPS (DRUPS).

Power in today's data centers is usually supplied by 2 independent inputs, each protected by its own uninterrupted power supply (UPS) and diesel generator sets DGS (Dieselgen) or diesel rotor UPS (DRUPS).

To objectively evaluate a data center’s capability of providing a certain level of service, they can be classified into levels of reliability. Today there exist 4 levels of data center reliability.

Tier I - Basic Data Center.

A Tier I data center is susceptible to performance disruptions arising from planned and unplanned activities. UPS and DGS in a Tier I data center are not mandatory, but are still used. They’re typically simple models with multiple fault points and no redundancy. At this level, data centers lack protection from intended and unintended human actions. Mistakes made by a service team can cause data center downtime.

Tier II - Data Center with Redundant Capacity Components.

This type of data center has a single, redundant UPS, DGS, and cooling systems. Downtime is reduced at a Tier II data center, but may still occur due to accidents and planned and unplanned events. Minimum protection against intended and unintended human actions are required under Tier II.

This type of data center has a single, redundant UPS, DGS, and cooling systems. Downtime is reduced at a Tier II data center, but may still occur due to accidents and planned and unplanned events. Minimum protection against intended and unintended human actions are required under Tier II.

Tier III and Tier IV data centers differ from the preceding types in their capacity for uninterrupted performance during planned operations.

Tier III - Data Center with Concurrent Capacity of Maintenance.

This type is also required to maintain the data center's uninterrupted performance in most cases of intended and unintended human actions.

Tier IV - Fault Tolerant Data Center.

This is the most reliable type of data center. In addition to the above reliability features associated with planned and unplanned events and human factor effect, it has to provide a capacity to withstand a serious failure without impacting a critical workload. Higher requirements apply to UPS and DGS redundancies.

To ensure the uninterrupted operation of a Tier III and Tier IV data center, it has to have a redundancy capacity to supply power to the components and systems through its redundant path.

Regardless how reliable the power input’s organization structure is, a single input may still fail. Here RPCM automatically switches the workload to the redundant path without interrupting power supplied to consumers.

Generally, however structured the power supply scheme is in a data center, each input has its own packet switch. If a short circuit occurs on one of the consumer devices, this will turn off the packet switch on the entire input. But if ATS is used, the entire rack will go offline.

You can purchase equipment with two power supplies to ensure reliability. But if you want the capability to remotely reset this equipment, then you’ll need a managed PDU on each power supply unit. The cost of 10 PSU and 2 managed PDU combined is exponentially higher than using equipment with a single PSU together with RPCM, which has ATS and outlet power management.

Alternative means currently available:

- managed PDU on each input + individual unmanaged ATS on each device

- managed PDU on each input + devices with two PSU

- common ATS per rack between inputs + a single managed PDU

- you can hope to encounter no problems, but if they do, you’ll have go to the facility and resolve them

Remote power management of individual outlets

Today everyone expects information systems to work round the clock.

And regardless of the reliability of a power supply on an input, equipment and software will occasionally fail and simply freeze up. It's fine if this happens during business hours, and the equipment is just situated in the next room with system administrators who know where to find what. They can quickly run over and “tug” at the power supply unit. But in most cases, problems happen spontaneously and outside of business hours. Also, the racks with the equipment could be located in various places (different addresses and even different cities and countries). And perhaps there may be no one nearby capable of locating and resolving the problem.

And even if you manage to send a tech support engineer to the data center’s server room during a failure, how long will it take him or her to identify the cause, and will he or she always manage to do this at all?

Perhaps it so happened that while working in the server room, engineers accidentally hit a power supply cable and spent a while determining why the device was unresponsive and inaccessible?

Thanks to RPCM’s remote power management feature, system administrators can turn on/off and reset any of the 10 outlets from off-site. And thanks to built-in power monitoring on each of RPCM's outlet, administrators can also handle cases where the equipment was either turned on/off without authorization, was accidentally unplugged, or experienced a power supply failure (RPCM can notify administrators about workload loss on the outlet, which will quickly help with locating the accidentally disconnected cable or power supply failure on the connected equipment).

Thanks to RPCM’s remote power management feature, system administrators can turn on/off and reset any of the 10 outlets from off-site. And thanks to built-in power monitoring on each of RPCM's outlet, administrators can also handle cases where the equipment was either turned on/off without authorization, was accidentally unplugged, or experienced a power supply failure (RPCM can notify administrators about workload loss on the outlet, which will quickly help with locating the accidentally disconnected cable or power supply failure on the connected equipment).

Outlet level short circuit (SC) protection

A short circuit is one of the most unpleasant things that can happen when specialists are using an equipment.

A short circuit is one of the most unpleasant things that can happen when specialists are using an equipment.

This happens rarely, but certainly. And it entails the painstaking task of having to locate it, which means services remain offline for a long time. And in a worst-case scenario, it can lead to a fire and considerable damage.

What causes short circuits?

The most common cause of a SC in a telecommunications and server equipment is either an explosion or failure of the electrolytic capacitor, diode bridge, or high-voltage transistor in impulse power supplies.

What happens during a short circuit if a common ATS rack connected to a power distribution supply via inputs is used?

Multiple power surges during a SC cause a trip in the power distribution supply's input switch where the main ATS input is connected. As soon as the main input goes off, the ATS performs its function by switching the load to the backup input. Insofar as the short circuit itself hasn't been eliminated, it affects the backup input, causing a trip in the backup input’s input switch. The entire rack goes offline, as a consequence.

The problem doesn’t end, but only starts there, as turning on the switches requires firstly that the equipment where the SC happened is located and switched off. As a rule, the only practical way to locate it is to physically disconnect all power cables on the rack, turn on the switches, and then connect all power device cables until the failed power supply is identified. When the cable to the failed power supply is connected, either another trip in the switches will occur, causing the entire equipment on the rack to turn off again (insofar as the SC has yet to be eliminated), or, in the best-case scenario, the engineer will see that the power supply didn't turn on.

What happens during a short circuit where RPCM is used?

If a short circuit occurs on one of the devices connected to RPCM, RPCM will automatically cut off only the power going to that device, thereby preventing the other connected devices from turning off, as well as all the others connected to the same busbar. Since ATS is used for backup power supply, short circuit protection helps prevent both inputs to the rack from being turned off, while also preventing the equipment's power supply on the rack from shutting down as a result of a short circuit on one of the consumers. It also helps obviate the painstaking process of having to locate the failed consumer affected by the short circuit prior to restoring power supply on the rack.

Power meters on each individual outlet

Commercial data processing centers can offer clients better prices on colocation when compared with competitors, as it's possible to measure power consumption for each client device.

Colocation is currently a highly developed data center service. The provider places client equipment in its data center, connects it to a power supply and communication lines, and provides full or partial service. The client expends a certain amount of power, which is obviously not free. Given that in order to account for power usage there must be a meter installed, an individual input meter on the rack, and a system for remote information collection and transmission from the power meters, implementing an individualized accounting of power usage for a client is practical only in cases where entire racks are leased. When a client leases one or a few units, no one bothers with accounting for power usage, though pricing will be based on the maximum capacity of the connected device's power supply.

The possibility of accounting for a client equipment’s actual power consumption enables a data processing center specializing in colocation services to offer clients lower minimum prices, while at the same time increasing its competitive edge on the market without harming profits .

RPCM allows users to arrange for granular accounting of power usage down to the individual, connected outlet, i.e. data centers can offer better prices to their clients, starting from the first unit sold to the client.

RPCM allows users to arrange for granular accounting of power usage down to the individual, connected outlet, i.e. data centers can offer better prices to their clients, starting from the first unit sold to the client.

In addition, RPCM’s ability to measure power consumption on each outlet makes it possible to locate technical issues relating to accidentally unplugged cables during technical work or microvibrations which over time cause contact to weaken. And it prevents fire hazards thanks to the possibility of setting consumptions limits on each individual outlet, which inhibits devices from exceeding nominal currents for the power supply.

Configurable electrical current consumption limits for each outlet

Why do fires occur in data processing centers and server rooms?

Over time isolation in parts of the equipment dries out and deteriorates, which causes intercoil leakage in chokes or leaks into the ground. In this case, current consumption starts to increase, and the damaged parts and possibly the underlying power cables begin to heat up. If this situation evades timely detection and goes unresolved, the onset of heat will exacerbate the problem and accelerate its development and may cause a combustion and fire.

Over time isolation in parts of the equipment dries out and deteriorates, which causes intercoil leakage in chokes or leaks into the ground. In this case, current consumption starts to increase, and the damaged parts and possibly the underlying power cables begin to heat up. If this situation evades timely detection and goes unresolved, the onset of heat will exacerbate the problem and accelerate its development and may cause a combustion and fire.

By using RPCM, system administrators can prevent fire hazards from occurring thanks to the possibility of setting individual limits on electrical current consumption on each outlet, administrator notifications, or automatically cutting off the power supply to the consumer that has exceeded the defined limit.

Customizable activation sequence and delay of outlets to initiate service correctly and eliminate inrush currents

When server equipment is used, there are two common, widespread problems that require attention to the sequencing of the equipment’s activation and service restoration after a complete power loss.

Problem 1:

Combined inrush currents can exceed the maximum current of the installed UPS on small hubs using low-capacity UPS, when an attempt is made to turn on the entire equipment all at once after an outage. As a result, the UPS will switch over to overload mode, and the device will simply not turn on.

Problem 2:

When turning on servers of information systems before infrastructure services (like a network, DHCP, DNS, NTP, AD) launch and start working, the servers of information systems can remain in an error status and in wait for manual intervention for them to be launched properly.

When using RPCM, system admins can essentially guarantee an equipment is turned on after a complete outage. Also, they can define the activation sequence and delay, when turning on the equipment after a complete outage, which allows them to launch the IT infrastructure and information systems in a proper manner.

Proper grounding diagnostics

Lack of proper grounding leads to:

- increased external electromagnetic interference impact on an equipment’s performance

- equipment failures as a result of lightning strikes

- the possibility that an equipment’s corpus may hold an electric charge, as result of which a person, who, by touching the corpus, may be electrocuted

RPCM prevents failures and equipment malfunction. It also increases power safety during equipment use thanks to automatic monitoring and proper grounding indication.